This project was made in 2016 for my final internship in the NHS Tayside Hospital, in order to get my Industrial engineering degree from INSA in France and my MSc in Biomedical Engineering from the University of Dundee in Scotland.

Background

Every year, 5 000 babies are born at Ninewells hospital according to the weight of the baby a specific amount of vitamin K needs to be administered to each of them, to avoid Vitamin K Deficiency Bleeding (hemorrhage).

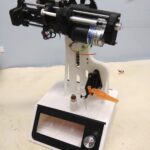

The aim of this project was to demonstrate the feasibility of a Syringe filling system to increase the precision of drugs injected and reduce the risk of human error, by studying the market for existing solutions and designing a prototype.

Features

- Needle sterilization preserved

- High precision dosage

- Filtered and 25G needles supported

- Intuitive interface

- Light and portable

- Fast operation

Manufacturing

The prototype was mainly 3D printed and few parts where machined using lathe and CNC mill.

Further work

- Improve the reliability of the system by adding control sensors, especially to control the dosage inside the syringe.

- Make evolve the design by considering every point of the medical device standards.

- Manufacture a prototype made of stainless steel.

Conclusion

This system is expected to make a big difference inside the neonatal ward, by taking away some pressure carried by the clinicians and at the same time ensuring an accurate syringe preparation, especially for premature baby injections where the amount is variable.