In 2012, I had the idea and the motivation to build a CNC machine by finding randomly a website that sells 3 axis CNC made of wood. id-conception It is where I took inspiration for my design. This was probably my first big project.

The base

The main structure is made of wood, the axis are only composed cheap of ball drawer slide. These materials make the CNC very cheap to make.

Screw driving axis

Standards M8 threaded rod are used to drive the axis.

Spindle support

The milling spindle is a wood router, made to support radial constrain, perfect for this application. The support is just a wood plate with a hole of the diameter of the router. A screw and a nut are adding to tighten the router.

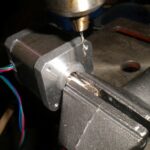

Coupling motor - axis

This part was very complicated to make. I tried may unsuccessful attempts before getting an acceptable result. Today we could easily order an aluminium flexible shaft coupler on the internet, but in that time I only had access to the hardware store. I finally used a long nut and a nail.

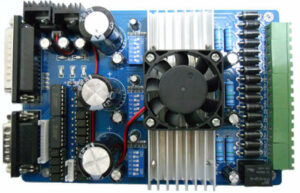

Electronics

The controller board I choose to use is a 3-axis TB6560. My uncle bought a complete kit for 100€ with the controller board, 3 stepper motors and the power supply.

Its main advantage is the price, however, it has some manufacturing defects that are quite annoying, like loss of steps during rotation due to bad signal level in the board. This is a fix that has to be done, and then the board is working fine.

Software

To design parts I use Solidworks, then I use the CAM (Computed Aided Manufacturing) software SolidCAM to generate the Gcode. That code is then open in Mach3 that controls the controller board. Mach3 is well design and has many features, one of them the backlash compensation is very useful. After measuring the play in one axis, the software will send extra steps to the board to compensate the play on each change of direction.

The board is connected to the computer by a LPT connector, used to connect printers. So an old computer has to be used…

Working !

Milling of depron to check the paths of the CNC

Usage